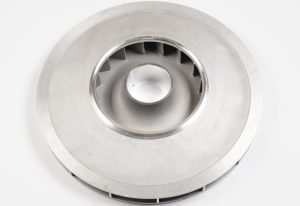

Aluminum alloy sand casting

Sand casting:

Sand casting is a traditional casting process that takes sand as the main molding material to make molds. Sand mold is generally cast by gravity, and low-pressure casting, centrifugal casting and other processes can also be used when there are special requirements. Sand casting has a wide range of adaptability, including small pieces, large pieces, simple pieces, complex pieces, single pieces and large quantities.

why choose us

1.Factory strength: The company has a construction area of more than 38,000 square meters and has an annual production capacity of 5,000 tons of aluminum alloy parts.

2.Casting process: The company has three casting processes: gravity casting, sand casting and high pressure casting, providing customers with the best manufacturing solutions, saving costs and improving efficiency.

3.Processing technology: Through vertical and horizontal machining centers (CNC), we can meet customer needs for high-speed, high-efficiency, high-precision, and high-rigidity products.

4.Production equipment: Aluminum alloy casting (sand casting, gravity casting, high pressure casting) Machining center (horizontal machining center, vertical machining center, CNC lathe, special machining machine) Testing equipment (three-coordinate detector, X-RAY testing equipment, spectrometer , tensile testing machine, hardness tester, cleanliness detector, ultrasonic thickness gauge, metallographic microscope, special leak tester) and other equipment more than 300 sets

5.Mold experience: with more than 10,000 molds from various manufacturers

6.Experience: Rich experience in OEM, support third-party audit

7.Certificate: The company has obtained IATF 16949 quality system certification

8.Quality assurance: 100% factory inspection

9.Provide support: provide personalized customization services and provide customers with design suggestions, resulting in lower costs and higher efficiency

10.R&D team: We have a professional design and R&D team, from mold design to mold manufacturing, providing value to customers with experience and technology, APQP tracking all stages

11.Modern production chain: The company has introduced automatic molding production equipment, which has accelerated the time of product sampling, and the fastest sample delivery is 15 days

12.Sales Network: Products are exported to North America, Europe, Middle East, Russia, Australia.

13.Scope of application: The company's products are widely used in auto parts, construction machinery, ships, new energy and other industries to provide customers with satisfactory products